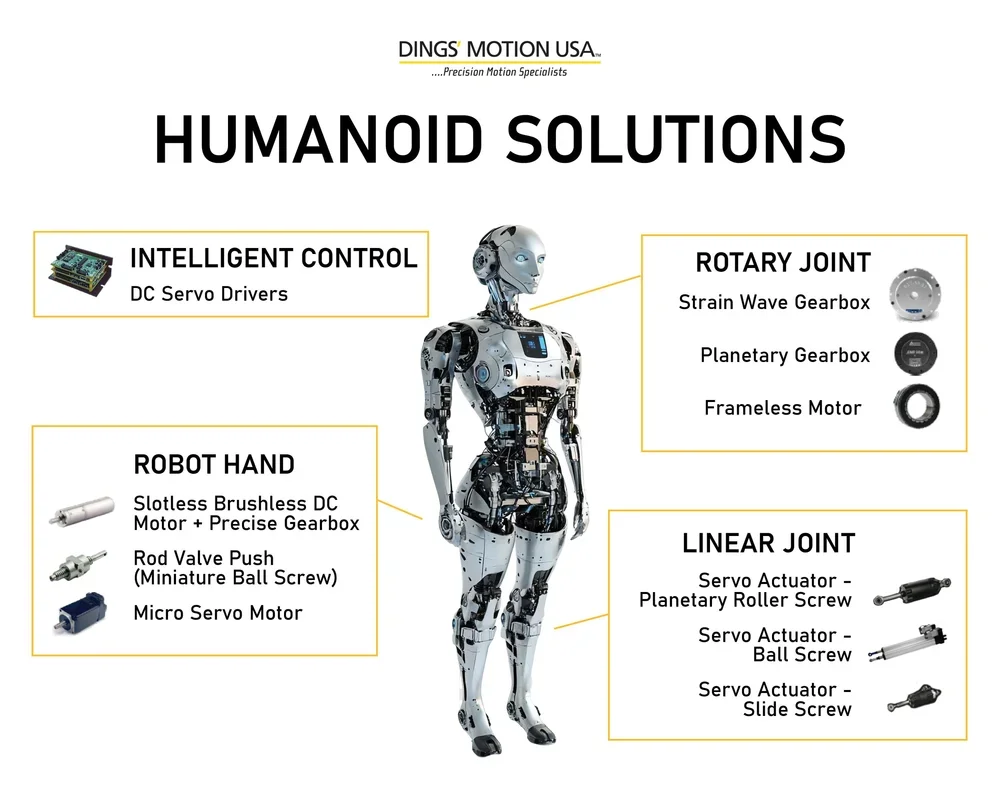

What It Takes to Make Humanoid Robots Move Like Humans: The Engineering Behind Joints, Hands, and Precision Control

Humanoid robots are designed to operate in spaces built for people, navigating stairs, manipulating tools, and interacting safely with human coworkers. Achieving this level of functionality requires far more than simply shrinking industrial robot components. Human movement is compliant, adaptive, and highly coordinated, while traditional robotic motion systems are optimized for rigidity and repetitive precision.

To bridge this gap, humanoid robots rely on densely integrated motion architectures capable of delivering high torque, smooth response, and real-time feedback within strict mass and volume limits. Every joint, limb, and finger must contribute to a dynamically balanced system where mechanical design and control algorithms are inseparably linked.

Translating Human Biomechanics Into Electromechanical Systems

Human muscles generate force through linear contraction while joints convert that force into rotational motion with natural damping and compliance. In humanoid robotics, these functions are recreated using combinations of rotary motors, gear reductions, and linear actuators that must respond predictably under constantly changing loads.

Key performance targets include:

· High torque density to support body weight and payloads

· Low reflected inertia to enable fast corrective movements

· Minimal backlash to maintain balance stability

· Thermal efficiency to prevent performance drift

Rather than relying on oversized motors, designers increasingly favor high-ratio transmissions paired with compact, high-speed servo motors, allowing joints to remain lightweight while still producing human-scale forces.

Rotary Joint Engineering: Balancing Torque, Precision, and Responsiveness

Rotary joints carry the highest mechanical burden in humanoid platforms. Hip, knee, and shoulder joints must handle both static loads from body mass and dynamic forces generated during walking, jumping, or lifting.

High reduction gear systems are typically required to multiply motor torque into usable joint output. However, increasing gear ratio introduces tradeoffs in backlash, compliance, and reflected inertia.

Strain wave (harmonic) gear mechanisms achieve large reduction ratios within extremely compact envelopes while maintaining near-zero backlash. This makes them particularly valuable in balance-critical joints where even small positional errors can destabilize the robot. Their elastic deformation characteristics also introduce slight compliance, which can help absorb shock loads during foot impact.

Planetary gear systems provide a more rigid transmission path with high mechanical efficiency and strong load capacity. They are often selected for joints that experience continuous torque cycling or environmental exposure, where durability and long-term reliability are primary concerns.

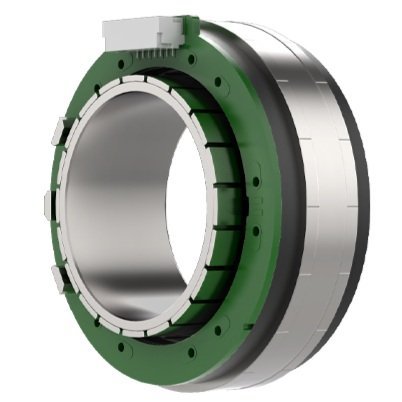

Frameless torque motors further optimize joint design by embedding the motor directly into the mechanical structure of the joint. This eliminates unnecessary housings, reduces weight, and allows heat to dissipate through the robot frame itself. The result is improved continuous torque capability and faster dynamic response, both critical for natural gait control.

Linear Actuation and Load-Bearing Dynamics

While rotary joints enable articulation, linear actuators play a major role in generating vertical forces, stabilizing posture, and absorbing mechanical shock.

In leg assemblies, linear actuators can function similarly to muscle-tendon systems, providing controlled extension and compression under load. These systems must manage extremely high axial forces while maintaining precise position control.

Roller screw mechanisms excel in these applications due to their distributed load contact geometry, which allows them to support several times the load capacity of traditional ball screws while maintaining long operational life. This makes them ideal for high-force joints such as knees and hips where repeated shock loading occurs.

Ball screw systems prioritize efficiency and low friction, enabling rapid, precise positioning with minimal power loss. They are commonly applied in joints requiring high-speed correction or fine positional control.

In vertical or load-holding scenarios, slide screw systems introduce inherent self-locking behavior, allowing joints to hold position without continuous motor torque. This reduces energy consumption and simplifies braking systems in certain postural control functions.

Dexterity at Human Scale: The Complexity of Robotic Hands

Hands represent a convergence of mechanical precision, sensor feedback, and control intelligence. Unlike large joints where torque dominates design priorities, robotic fingers demand extremely fine motion resolution combined with rapid response.

Low inertia is critical, as heavy motor assemblies limit the ability to perform fast micro-adjustments required for stable gripping. Slotless brushless motor designs reduce magnetic cogging and torque ripple, producing smoother motion profiles that translate directly into improved manipulation accuracy.

Micro-scale linear actuation, often using miniature ball screw systems, converts rotational motion into precise finger extension and flexion. This approach allows force amplification while maintaining tight positional control, enabling hands to perform tasks ranging from delicate object handling to firm grasping.

The real challenge lies in synchronizing multiple finger actuators while responding to tactile sensor feedback in real time, a task that pushes both mechanical and computational limits.

Control Architecture: Where Mechanics Meet Intelligence

Mechanical precision alone cannot produce human-like motion. Humanoid robots depend on distributed control systems that continuously adjust torque, speed, and position based on sensor data.

Modern platforms employ networked servo drives communicating across real-time protocols such as CAN Bus and high-speed serial networks. Integrated encoders feed joint position and velocity data into control loops operating at kilohertz update rates.

These closed-loop systems enable:

· Active balance correction during gait cycles

· Impact absorption during foot contact

· Adaptive force control during manipulation

· Energy-optimized motion trajectories

As humanoid autonomy increases, the coupling between actuation hardware and control software becomes tighter, requiring motion systems specifically engineered for rapid feedback responsiveness.

Fully Integrated Motion Subsystems

A growing trend in humanoid robotics is the shift away from discrete component assembly toward integrated joint modules that combine motor, gearbox, sensors, and drive electronics into compact units.

This integration reduces wiring complexity, minimizes signal latency, improves reliability, and accelerates mechanical design iteration. It also allows thermal management strategies to be built directly into the joint structure.

DINGS' Motion USA supports this evolution by developing integrated rotary joints, linear servo actuators, robotic hand solutions, and intelligent control architectures specifically aligned with humanoid robotic demands.

The result is motion infrastructure that behaves less like traditional industrial automation and more like a cohesive biomechanical system.

The Path Forward

As humanoid robots transition into real-world environments, motion systems will continue evolving toward higher power density, lower mass, greater efficiency, and deeper integration with sensing and control intelligence.

Success will not come from any single technological breakthrough but from the optimization of complete motion ecosystems where mechanical design, actuation technology, and real-time control are engineered as one unified system.