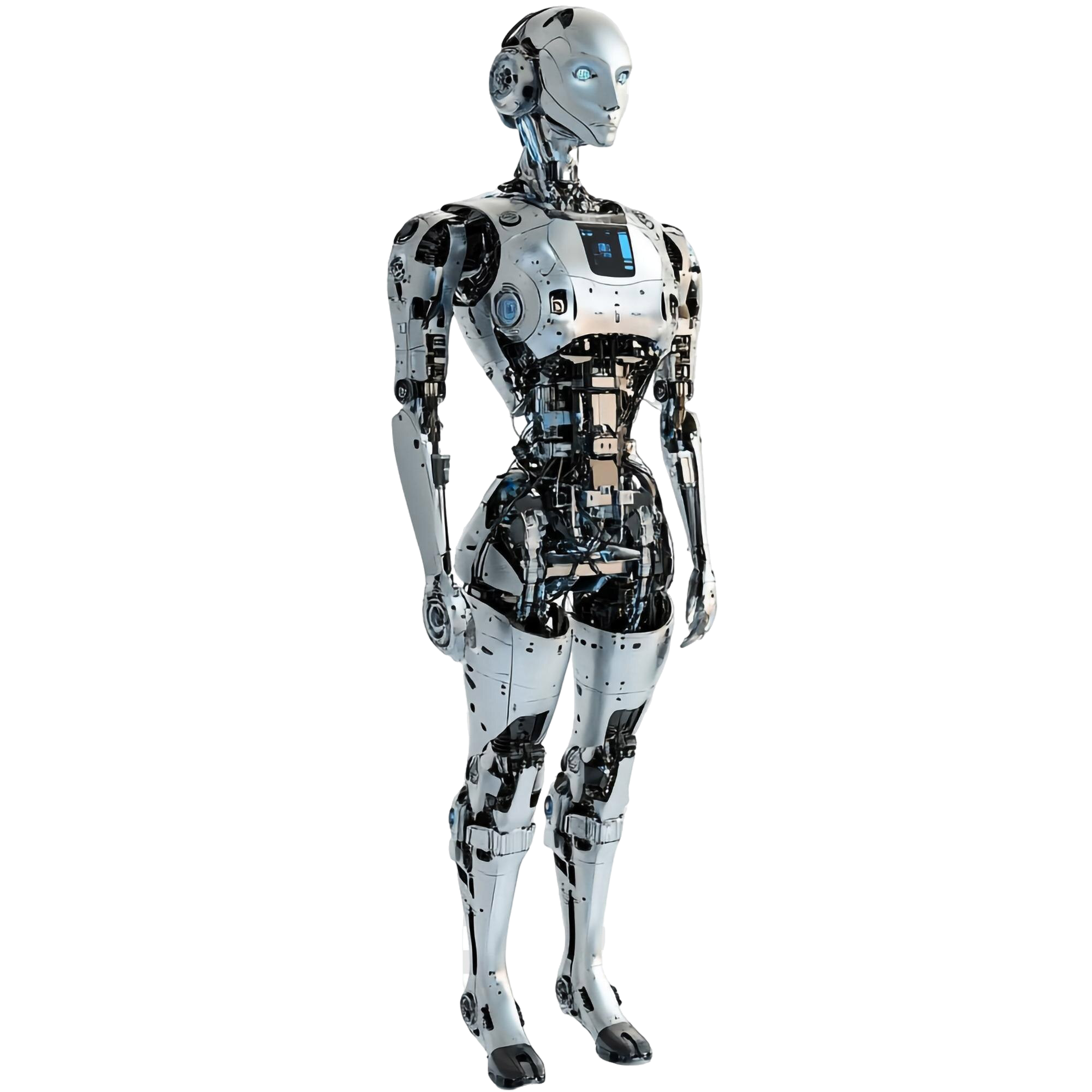

Case Study

Enabling Compact, Efficient Joint Design in Humanoids with Hollow Shaft

CLIENT BACKGROUND:

Many of our robotics clients operate in the robotics and humanoid sector, where compact design, wire routing, and motion performance are critical for building intelligent, human-like systems. Each robotic joint typically requires multiple motors, creating wiring challenges that impact design efficiency and aesthetics.

TECHNICAL REQUIREMENTS:

Motion Types:

Direct drive, planetary drive, and harmonic driveEnvironment:

Robotics R&D and prototypingCritical Needs:

-Integrated wire routing

-Compact joint design

-Versatility across motor types/sizes

CHALLENGE:

In humanoid robot arms, routing wires externally around each joint motor was inefficient and disrupted the compact, integrated design engineers aimed to achieve. Our customers desired a more elegant solution to streamline wiring and improve mechanical integration.

CUSTOM SOLUTION:

To solve this wiring challenge and improve mechanical integration, we introduced hollow shaft servo motors across multiple series:

• RMD-X Series (Planetary Gear Drive)

The hollow shaft allows internal routing of wires through the motor body, simplifying cable management and enabling a more compact, clean design for humanoid arms and joints.

These product enhancements are now part of our standard offering, available in multiple frame sizes and gear ratios to meet various application needs.

RESULTS:

The custom solution has been a game-changer for the humanoid industry. Key results included:

PERFORMANCE

OUTCOMES

With the hollow shaft design, engineers now route wires directly through each joint motor, leading to a neater, more compact architecture in humanoid limbs. This enhancement improved design flexibility and reduced time spent managing cables during assembly.

QUANTIFIABLE

IMPACT

The simplified wiring reduced mechanical complexity and streamlined robot design processes.