Case Study

Precision Motion for Lab Automation:

Enhancing Well Plate Detection with a

Custom XY System

CLIENT BACKGROUND:

The client is a leading provider of liquid handling validation technologies, supporting laboratories with precision tools for well plate level detection and fluid analysis.

TECHNICAL REQUIREMENTS:

Stroke Length:

116mm (X-axis), 200 mm (Y-axis)Load Capacity:

>5 lbsSpeed:

50mm/sVoltage:

24VDuty Cycle:

LowEnvironment:

Laboratory UseMounting:

Dual-carriage DLM system

CHALLENGE:

The client needed a compact, high-speed XY motion system suitable for laboratory bench-top environments. Their existing belt-driven design lacked the necessary accuracy and required frequent maintenance—hindering performance and long-term reliability.

CUSTOM SOLUTION:

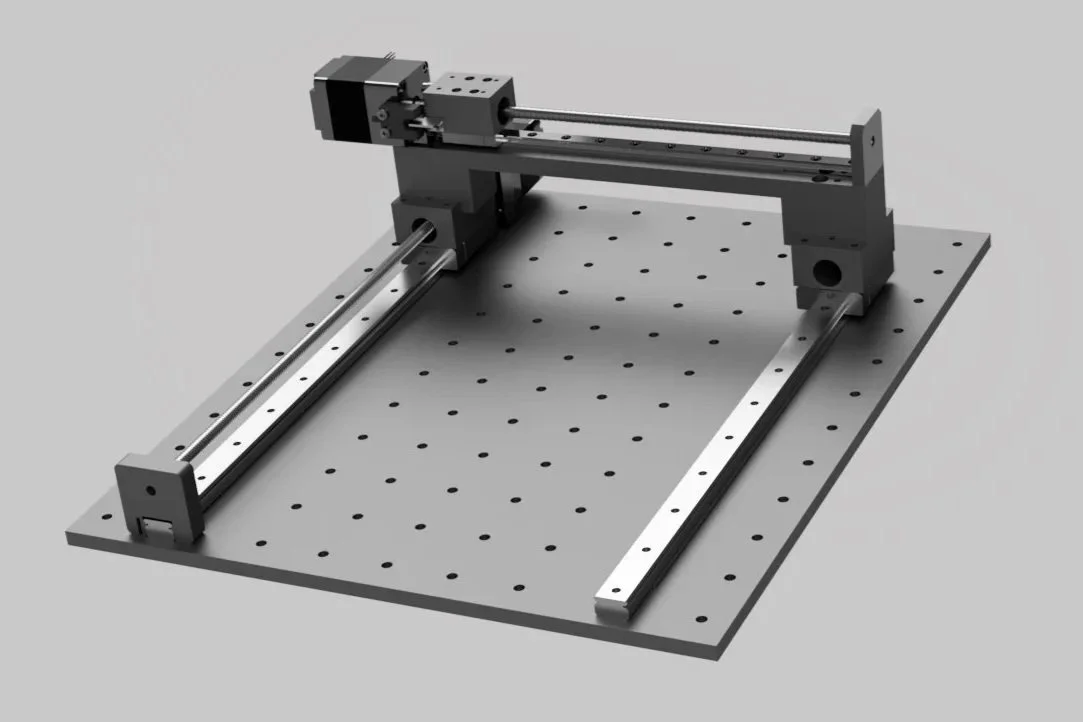

We initiated the project by supplying standard DLM actuators from our Quick Ship Inventory, enabling rapid process validation. Following successful trials, we collaborated with the client to engineer a custom XY system that met their demanding performance criteria.

Key Customizations Included:

Custom baseplate & X-axis bridge to accommodate design constraints

Anti-backlash leadnuts for improved precision

Dual-carriage design for added load support

Integrated homing sensors

Turnkey XY system delivered fully assembled to reduce client assembly time

RESULTS:

The custom solution significantly improved performance. Key results included:

PERFORMANCE OUTCOMES

The custom motion system preserved the high speed of belts while significantly enhancing positional accuracy. It also eliminated the need for regular maintenance.

QUANTIFIABLE IMPACT

By delivering a complete XY system, we reduced the client’s bill of materials and alignment steps—minimizing instrument assembly time and lowering the risk of integration issues.