Ball Screw and Nut Assemblies

DINGS’ MOTION USA

DINGS’ Motion USA provides high precision ball screw and nut assemblies designed for smooth, efficient, and repeatable linear motion across robotics, laboratory automation, medical devices, semiconductor systems, and industrial equipment. Each assembly features optimized recirculation structures, tight lead accuracy, and strong load-carrying capability to support demanding OEM requirements.

If you require guidance in choosing the appropriate screw or nut, please feel free to reach out to us for assistance.

Ball Screw Nut Assemblies

DINGS’ Motion USA offers a full range of ball screw nut assemblies engineered for smooth, accurate, and efficient linear motion. Nut styles include flanged, cylindrical, threaded, and square designs to support a wide variety of mounting and packaging requirements. Available in precision grades from C3 ground to C10 rolled, these assemblies provide stable lead accuracy, low friction, and long service life. Materials, raceway geometry, and recirculation structures are optimized to deliver reliable performance in robotics, laboratory automation, medical devices, and industrial equipment.

-

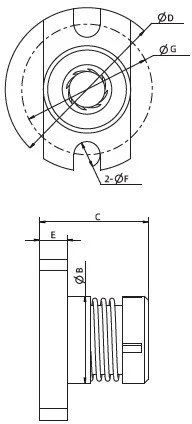

FBG / FBR Flanged Single Nut

For 4mm - 12mm DIA Screws

-

CBG / CBR Cylindrical Single Nut

For 4mm - 6mm DIA Screws

-

MBG / MBR Metric Threaded Single Nut

For 4mm - 10mm DIA Screws

-

KBG / KBR Square Single Nut

For 6mm - 8mm DIA Screws

Ball Screw Options

DINGS’ Motion USA provides ball screws in a wide range of diameters from 4 mm to 25 mm, with options in C3 and C5 ground precision or C7 and C10 rolled versions. Engineers can select from multiple lead choices, custom lengths, and end-machining configurations to match specific load, speed, and accuracy requirements. Internal and deflector recirculation designs support compact packaging, smooth ball return, and stable motion at varying duty cycles. These options allow OEMs to tailor ball screw performance for robotics, lab automation, medical devices, and precision industrial equipment.